Water base flexographic inks have been used for printing on the flexible packaging manufactured by Brown & Pratt, Inc. since the 1980’s. As the technology of water-based inks changed, we too adjusted to ensure top quality printing on all custom bag orders.

The adhesion of the water-based inks we currently use is durable enough to withstand the wear-and-tear to which a mailing bag, retail bag, and all other printed items are subjected to through their useful life.

Call: 888-353-1664

Although significant improvements have been made to water-based ink technology, the main prohibitive environment for water-based inks is in freezer applications where there is a possibility that condensation will form on the poly film surface or where ammonia is present causing the ink to loosen its grip. In freezer applications, solvent ink is resistant to the effects of condensation.

Brown & Pratt can trap water base ink colors by overprinting using a couple of the colors in the job. Solvent inks are the best choice in a freezer application when flexo printing is required on polyethylene or polypropylene flexible packaging since solvent ink does not lift when the bag is subjected to the condensation from the freeze/thaw cycle.

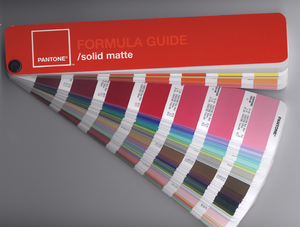

For our artwork and printing specialists to best match your precise color when printing, we must reference your specific Pantone Matching System (PMS) color. PMS is a standardized color reproduction system that allows different printers to accurately match the over 2,000 different shades and colors available for printing. To best locate your precise color, you can utilize our online chart to find your exact match.