WE ARE DEDICATED TO FULFILLING ALL YOUR PACKAGING NEEDS WITH EXCEPTIONAL SERVICE

The Dry Ice Challenge: Packaging for Shipping Frozen Baby Food to Customers

Case study

Tiny Organics: Organic Baby and Toddler Meals Delivered to Homes.

Shipping perishable, frozen meals to parents anxious to give their children the very best puts high-stakes pressure on safe packaging.

Case Study highlights

The right packaging when you need it, where you need it.

01. Collaboration

Finding the Sweet Spot Between Client Vision and Vendor Realities

02. Packaging Specs

The Dry Ice Challenge for a Durable, Branded, Cost-Effective Box

03. Flexibility

Making Adjustments Along the Way Based on Feedback

04. Logistics

Bulk Ordering with Multiple Delivery Locations for Customer Convenience

Collaboration

Finding the sweet spot between client vision and vendor realities

Exploring options, estimating costs, arriving at a solution

When the realities of what the client’s vision costs them come to light […] then they have the opportunity to think more deeply

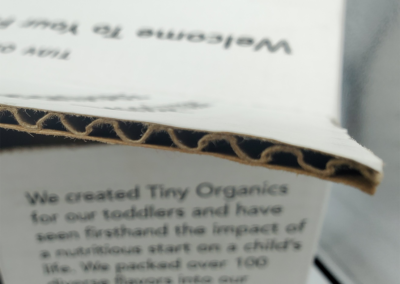

Tiny organics found their way to Brown & Pratt via our website, and they had a clear vision of what their packaging would look like. It would be a mailer box that has the look and feel of a gift box, and they envisioned extensive brand printing on the box including a half-dozen different colors. They saw this type of box as something families would keep and reuse, thereby extending the branding effect. This kind of box carries substantial tooling costs (thousands of dollars up-front), as well as more expensive printing with so many colors of ink. In addition, this type of box comes with limitations in how much product it can accommodate—they’re designed for smaller quantities.

In some cases, clients don’t really have any vision at all, and it takes time to help them figure out what they want. But in this case, the client had a clear vision, but when the realities of what their vision will cost them come to light—an unpleasant but necessary part of the collaborative relationship—then they have the opportunity to think more deeply about what will meet their needs while also being affordable and acceptable in terms of cost.

In this case, the clients quickly realized they were probably going to be larger quantities, which meant a larger shipping box would be needed. And if they became loyal customers, they would be receiving shipments on a regular basis, which meant customers would probably be looking to recycle the box and not saving it for reuse. Between the expense, the higher quantities, and no need to reuse, they made the decision to go with a more standard corrugated shipping box called an RSC (regular slotted carton) box.

Packaging Specs

The Dry Ice Challenge for a Durable, Branded, Cost-Effective Box

Including Interior Elements: Corrugated Separators, Foam Inserts

We started them off with a single-wall standard corrugated shipping box. The challenge in this case is keeping the food frozen through the shipping process, and the only practical way to do that is adding dry ice in the box. The client also had a vision for how the interior packing of the shipping box would work and look, and we were able to go with their vision.

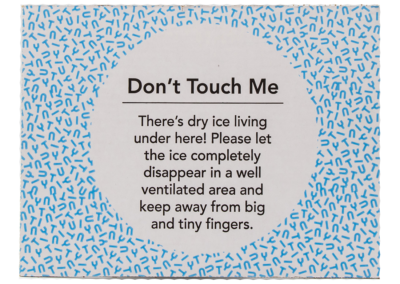

Upon opening the box, there is a top corrugated sheet with branded text to alert customers that all the meal containers are in the top layer. When the meal containers are unpacked and put in the freezer, they encounter another branded corrugated sheet that alerts them to the dry ice below and how to safely deal with and dispose of it.

There also needed to be foam inserts as part of the interior packaging, and because this is an organic brand, they went with biodegradable foam and provided information to customers on how to properly dispose of the foam in their kitchen sink with running water to dissolve it.

The challenge is keeping the food frozen through the shipping process. The only practical way to do that is adding dry ice in the box.

flexibility

Making Adjustments Along the Way Based on Feedback

Increasing Box Durability to Withstand Shipping with Dry Ice

The solution to this dilemma was simply increasing the thickness of the box enough to prevent shipping failure.

The client soon discovered, however, that the initial single-wall box type was not up to the challenge of shipping, which was a big learning point for them and us. Every package that goes through a shipping process gets handled six or seven different times, and they aren’t always “handled with care.” In other words, shipping is a rough process and packages get tossed around a lot.

Combined with rough handling were issues created by the presence of dry ice in the box. As dry ice evaporates, some amount of moisture vapors are created in the box that can still get around the foam inserts. The further the distance that box must travel and the more moisture is created, it can get into the corners of the box and weaken their structural integrity. The box gets tossed around by shippers and might arrive at its destination in pretty bad shape. This is problematic when the product is food for babies and toddlers. Parents might be wondering if the food is still safe, which is obviously not going to help with brand loyalty.

The solution to this dilemma was simply increasing the thickness of the box enough to prevent shipping failure, which also raises the cost of the box, but it had to be done. This raised an additional interesting dilemma. Some shipments that didn’t need to go very far could easily get by with the original single-wall box, so should they have two different box styles depending on how far the order needed to be shipped? This is an approach taken by some. But when we ran the numbers, it became apparent that smaller production runs of two different types of boxes would cost more than bulk-buying larger runs of the thicker box. This helped the client make the decision to use the thicker box across-the-board because they knew it would work for all shipments without fail and was the more cost-effective solution.

logistics

Bulk Ordering with Delivery to Multiple Locations for Customer Convenience

Working with the Client to Make Inventory Acquisition Simple

We always look to solve the pain points our clients experience. That’s just the right way to do business.

Because Tiny Organics is growing rapidly, they need to ship products to consumers from multiple locations and have their packaging materials available at those locations. The way this is handled at many packaging vendors might go something like this: They run a big order of packaging materials, packaged up as one big order, and will send it to the client’s main or central location, this leaves the client to figure out how to divide up the order and get the right quantities out to additional ship-from locations.

At Brown & Pratt we pride ourselves on not being like most packaging vendors. We’re always looking for ways to solve the pain points our clients experience because that’s just the right way to do business and maintain strong partnerships with our clients.

In this case, although Tiny Organics is ordering their packaging and shipping products in bulk, we don’t treat the order as a single bulk order. We take on the task of dividing the order up into multiple shipments to their various shipping facilities. We make sure each facility gets everything they need—it obviously is no good if they receive boxes without the corrugated separators—and perform this valued-added logistics service at no additional charge. Needless to say, the client is very pleased with the results.

Brown & Pratt: Your Custom Printed Packaging Partner

When you need shipping and packaging solutions that extend and reinforce your company’s brand, Brown & Pratt is ready to help with custom printed boxes, bags, and tape.